Make Your Dust Collection System a Reality!

Breathe Easy: Revolutionize Your Woodworking Shop with Effective Dust Collection

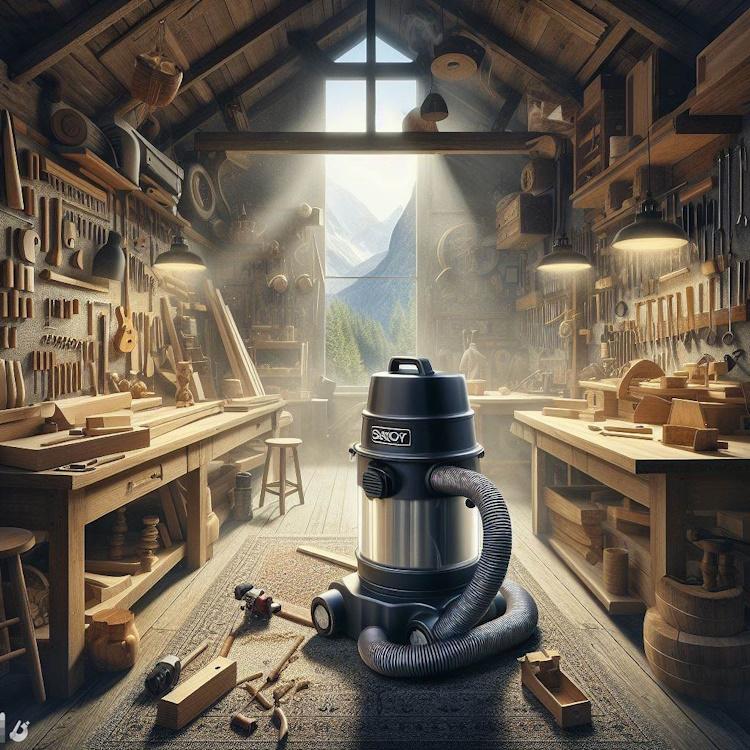

A woodworker in a clean and organized workshop with a dust collection system in action.

Woodworking is an art, a craft that transforms raw timber into beautiful creations. But, every stroke of the saw, every spin of the lathe, and every pass of the planer generates dust. If not managed properly, this dust can create a messy workspace and pose health risks. Enter the solution: Woodworking Shop Dust Collection.

A well-designed dust collection system for your woodworking shop keeps your shop clean and tidy and ensures a healthier and safer environment to unleash your creativity. It’s not just about cleanliness. It’s about your health, your tools’ longevity, and your work’s quality.

Imagine working in a shop where the air is clear, your tools are always ready to perform at their best, and every detail of your craftsmanship shines through without the haze of dust. That’s the benefit of a woodworking shop dust collection system. It’s an investment in your shop’s efficiency, the quality of your work, and, most importantly, in you.

So, let’s dive in and explore how you can revolutionize your woodworking experience with effective dust collection. Because every woodworker deserves a clean, safe, and efficient workspace. In every woodworking shop, let’s make dust collection a standard, not an afterthought.

Ready for fresh air? Let’s dive in!

Key Takeaways

- Woodworking dust is harmful and can cause health problems, so using a dust collection system is very important for your lungs and to keep the shop clean.

- There are different types of dust collectors, like shop vacuums, air-filtration systems, single-stage and two-stage collectors. Each one works best for certain jobs and budgets.

- Good airflow in a dust collector helps catch more sawdust. You will need hoses or pipes to carry the dust from tools to the collector.

- Keep your woodworking space in mind when choosing a dust collector. Make sure it fits well without taking up too much room.

- Take care of your equipment by cleaning filters and checking for blockages often. This makes sure everything keeps working right to help you breathe easier while you work.

Basics of Effective Dust Collection Systems in a Woodworking Shop

Dust collection in a woodworking shop is crucial for maintaining a clean and safe working environment. Common equipment used includes shop vacuums, air-filtration systems, and single or two-stage dust collectors.

Good airflow is essential for effective dust collection, and there are several factors to consider when choosing the right system for your workshop space.

Importance of Dust Collection

Think of how much sawdust flies around with every cut and sand – that’s why it’s super important to have a strong dust collector hooked up to your tools. A good system sucks up wood chips and dust right where they’re made, keeping both the air and your workspace cleaner.

Having a top-notch dust collection setup means you can work safer and smarter. You get fewer messes on floors and machines, making moving around and doing great work easier. Plus, systems today are built better than ever, fitting all kinds of budgets while protecting your health.

That’s smart shopping for any level of craft or size of shop!

Small Woodworking Shop Under $1,000

Advertisement

Common Dust Collection Equipment

- Dust Extractor: This powerful vacuum sucks up dust and debris straight from your tools. It works great with things like table saws, miter saws, and sanders.

- Hoses and Pipes: These carry the dust from your tools to the dust collector or extractor. You’ll want strong hoses that can handle the sharp bits of wood without getting holes.

- Blast Gates: You use these to control where the suction goes in your system. Close them when a tool isn’t being used to boost suction where it’s needed most.

- Air Filtration System: While collectors grab big chips, an air filtration system cleans tiny particles from the air. It’s like a giant air purifier for your shop.

- Cyclone Separator: Before dust gets to your filter, this spins it around in a big funnel. The heavy stuff falls into a bin, which helps keep your filter cleaner longer.

- Filters: All that fine sawdust has to be caught by something! Filters trap small particles so they don’t go back into the air or hurt the motor in your collector.

- Dust Bags and Bins: These are where all the collected sawdust ends up. Bags are disposable, while bins can be emptied out and reused.

Types of Dust Collectors

Dust collectors come in various types, including shop vacuums, air-filtration systems, and single or two-stage dust collectors. Each type has its own unique benefits and features, so it’s important to understand the differences when choosing the right one for your woodworking shop.

Shop Vacuum

A shop vacuum is a must-have tool for cleaning up sawdust and wood chips right where they happen. Think of it like a superhero that sucks up all the mess, keeping your workspace tidy and safe.

These strong vacuums are built to handle the big pieces and fine particles from tools like table saws, planers, and bandsaws.

But it’s not just about cleanliness; using one reduces the risk to your health. Fine dust can be really bad for you if you breathe it in. That’s why sucking up those tiny bits with a shop vacuum matters so much—it’s about taking care of yourself while you create something great out of wood.

Air-filtration System

After setting up a shop vacuum for the larger debris, an air-filtration system becomes crucial to tackle the fine dust particles that are still lingering in the workspace. These systems work by continuously filtering and recirculating air, capturing airborne particulates down to 0.3 microns in size.

By doing so, they improve air quality and reduce health risks associated with inhaling fine wood dust particles.

A well-designed filtration system can effectively remove harmful particulates from the air, promoting a healthier working environment for woodworkers. Additionally, easy access to replacement filters and regular maintenance are key factors ensuring optimal performance of the air-filtration system.

Single Stage and Two Stage Dust Collectors

After considering air-filtration systems, it’s essential to understand the difference between single-stage and two-stage dust collectors. Single-stage dust collectors are simpler and consist of a single container where debris is collected, while two-stage dust collectors have a separate first stage for capturing larger particles before finer particles enter the main filtration system.

This distinction impacts efficiency and maintenance needs.

Single-stage units are more budget-friendly but may clog more frequently. On the other hand, two-stage models offer better airflow and require less frequent emptying due to their ability to capture larger debris first.

Understanding the Importance of Maximizing Airflow for Dust Control

Understanding the Importance of Airflow in Dust Collection, a woodworking shop filled with sawdust particles suspended in the air.

Sufficient airflow is crucial for a dust collection system to effectively remove harmful airborne particles. Without proper airflow, the system may not capture all the dust which could lead to health hazards.

To ensure efficient airflow, it’s essential to consider the air volume measured in Cubic Feet per Minute (CFM). A high CFM rating indicates better suction power, enabling the collector to pull in more dust from woodworking machines.

Additionally, understanding how air moves through ductwork and fittings is vital. Properly sized ducts and strategically placed blast gates can help maintain airflow throughout the entire system, preventing clogs or reduced suction at individual machine connections.

Maintaining adequate airflow also prevents fine dust from settling back into the workspace after being captured by the collector. This reduces health risks associated with inhaling fine particles that are invisible to the naked eye yet pose significant dangers over time.

Properly designed systems with optimal airflow contribute to cleaner air quality in woodworking shops, enhancing overall safety for woodworkers while creating a healthier work environment for everyone involved.

Factors to Consider in Choosing the Right Dust Collector

Consider the size of your shop space, the amount of dust generated by your tools, the noise level you can tolerate, and your price range when choosing a dust collector. Read on to discover which type of collector is best suited for your needs.

Shop Space

Factors like the layout of machines and the overall size of your woodworking shop will determine the best placement for dust collectors and air filtration systems. Consider the dimensions and accessibility when selecting the right equipment to ensure it doesn’t overcrowd or obstruct your workspace.

Proper utilization of shop space ensures an effective and safe woodworking environment.

Taking into account industry standards indicating that on average every twenty pounds of sawdust can pose health risks, finding room for dust collectors becomes crucial in maintaining a clean air environment within confined spaces.

Dust Generation

Collecting the dust at its source is not well understood. It’s crucial to have enough air volume for effective dust collection. Dust collectors should take away most of the dust and wood chips to keep us safe.

Implementing good dust collection in woodworking makes the environment healthier. The industry now offers safer products for all budgets because it takes this issue seriously. It’s important for safety and health in woodworking shops to have good systems to collect dust.

Noise Level

Reducing noise levels is crucial when considering a dust collector for your woodworking shop. The sound generated by the equipment can impact the comfort of your workspace and even productivity, so choosing a system that operates at an acceptable noise level is important.

Quieter systems are available from various manufacturers like Grizzly, Festool, and others, providing efficient dust collection without being disruptive. Additionally, remote control options allow you to adjust the settings without approaching the machine directly.

Implementing a dust collection system with lower noise levels contributes to a more pleasant working environment and reduces potential distractions or disturbances caused by loud equipment.

Price Range

Dust collectors come in a range of prices, allowing for options that fit different budgets. Prices can start at around $100 for basic shop vacuums and go up to several thousand dollars for high-capacity, industrial-grade systems.

Factors such as airflow capacity, filtration efficiency, and noise levels can affect the price of dust collection equipment. It’s important to consider these factors alongside your woodworking needs when determining which system fits within your budget.

When choosing a dust collector, carefully weigh the features against the cost to find the best value for your specific workshop requirements. Remember that investing in a quality dust collection system is essential to creating a safer and healthier work environment while protecting your long-term health from harmful wood dust exposure.

Best Practices for Setting Up a Dust Collection System

Positioning of collectors is crucial for optimal dust collection. Regular maintenance of equipment and proper airflow management are also essential for effective operation.

Positioning of Collectors

Positioning your dust collector to efficiently capture the dust and chips generated by your woodworking machines is essential. Place the collector as close as possible to each machine to ensure maximum suction power.

Consider using a flexible hose or pipe and strategically placed blast gates to connect each machine to the collector. This allows you to direct airflow precisely where it’s needed, maximizing efficiency and minimizing energy consumption.

Remember that proper positioning of collectors is crucial in effectively controlling airborne sawdust particles within your shop.

Your woodshop’s layout will affect how and where you position your dust collection system collectors. Take into account the arrangement of machinery, workbenches, and other equipment when determining optimal placements for ensuring effective dust collection throughout your workspace.

Maintenance of Equipment

Now that your dust collection system is properly positioned keeping your equipment well-maintained for optimal performance is crucial. Regular maintenance of your dust collector and air filtration system is essential in ensuring they effectively remove harmful fine dust particles from the air.

This involves cleaning or replacing filters as needed, checking for any leaks or blockages, and inspecting the overall condition of the equipment to prevent malfunctions. Proper maintenance not only prolongs the life of your dust collection system but also ensures a safer and healthier woodworking environment by efficiently capturing airborne particles that can pose serious health risks.

To maintain equipment like shop vacuums and air-filtration systems, regularly check and clean their filters, hoses, and collection bags to ensure consistent airflow and suction power.

Maintaining a Healthy Woodshop Environment

In wrapping up.. think about the simple steps you can take to improve your woodworking shop’s air quality. Try out these practical tips for efficient dust collection. How will you implement what you’ve learned? Consider the positive impact on your health and workspace.

Remember, a clean and safe shop leads to better work outcomes. Keep exploring ways to enhance your woodworking experience!

Dust Collection System Brands for Small Shops

I can suggest some brands of dust collection systems for small woodworking shops based on the web search results I found. Here are some of them:

| Brand | Features |

|---|---|

| JET JCDC-3 Cyclone Dust Collector | Cyclone dust collector, 3 HP motor, 1240 CFM airflow, remote control, 66-gallon drum capacity |

| Festool HEPA Dust Extractor | Dust extractor, HEPA filter, self-cleaning mechanism, variable speed control |

| Shop Fox W1666 Dust Collector System | Dust collector system, 2 HP motor, 1550 CFM airflow, 2.5 micron filter, 5.4 cubic feet bag capacity, safety switch |

These brands will give you some ideas about which features you can use for comparisons.

FAQs

1. What parts do I need for my woodworking shop dust collection system?

You’ll want to gather accessories like a jointer, elbow, flange, and a sturdy dust bin for your system. Brands like Shop Fox and Powermatic offer these parts to help make assembling your setup easier.

2. How do I choose the right dust collector for my basement workshop?

Look at brands such as Powertec or Vacmaster who specialize in creating systems that can fit into smaller spaces like a basement. Compare their features with others like Bucktool or Oneida to find one that suits your needs.

Life Saving Dust Collection For Small Woodworking Shops (wherecanibuythat.us)

3. Can you give me some tips on installing my dust collection system?

Sure! Start by planning your design thoughtfully; ensure all machines are connected properly using elbows and flanges. Follow safety guidelines carefully, checking each part is secured tightly.

4. Why is maintaining my woodworking shop’s dust collection system important?

Regular maintenance keeps your system running efficiently—cleaning filters, emptying the dust bin, and checking connections ensure the air stays clean and that machines perform well.

How To Equip A Woodworking Shop Like An Expert From The Start (wherecanibuythat.us)

5. What should I look out for when troubleshooting my dust collection system?

If performance drops or there’s more dust around than usual, check if any filters are clogged or if any of the joints have come loose—you might need some adjustments!

6. Are there any special features of a well-designed woodshop air cleaner?

A good air cleaner has strong suction power and effective filters that catch even tiny particles so everyone can breathe easily while working on their projects.