Why Elite Woodworkers Want Japanese Wood Chisels

Keep Your Craftsmanship Sharp with Japanese Wood Chisels

Many veteran woodworkers consider Japanese wood chisels the best wood chisels you can get. For one thing, almost all Japanese wood chisels are individually hand-forged by a single craftsman. The biggest selling brands may not identify the craftsman involved in the making, but you can be reasonably sure that the process is the same.

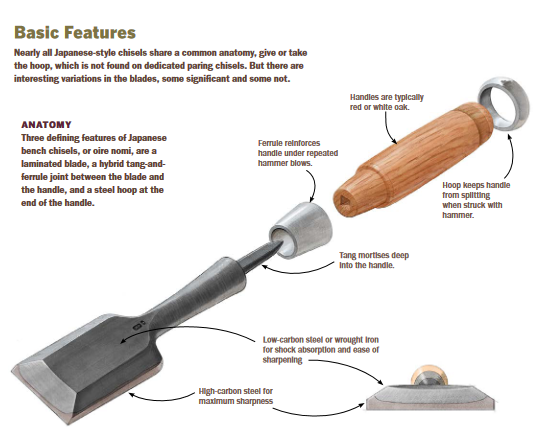

Japanese wood chisels are laminated in the same fashion as the famous Samurai sword. The cutting edge is a thin layer of very hard, high-carbon steel forge-welded to a thicker piece of low-carbon steel that forms the blade’s body. The thicker layer of soft metal absorbs the vibrations and shocks from hammering. The cutting edge can be quickly honed to maximum sharpness.

What’s Different About Japanese Wood Chisels That Make Them So Good?

This image from Woodworking with Hand Tools – Tools, Techniques & Projects illustrates the basic anatomy of a Japanese wood chisel.

White Paper Steel and Blue Paper Steel

The major distinguishing characteristic of the Japanese chisel or nomi is that the working end is forge-welded from two different metals. The blade’s body is made from low-carbon steel or a wrought iron core. The cutting edge is made from high-carbon steel with relatively few alloys.

The two varieties of high-carbon steel used for the cutting edge are manufactured by Hitachi and are shipped in white or blue wrapping paper. Hence, the names “white paper steel” and “blue paper steel.” You may see this distinction when shopping for Japanese chisels. The difference between them is not major. Blue steel has tungsten and chromium alloys and is considered more resilient to abrasion. White steel is easier to sharpen. Both will hold a sharp edge.

Japanese wood chisels have sharper, more durable edges than their Western counterparts because the Japanese chisels are commonly hardened to Rockwell 64 on the C scale. Western woodworking chisels typically have a Rockwell hardness in the 60-62 range. Furthermore, the repeated hammering in the forge-welding process causes the steel’s carbides to become very small and evenly distributed, allowing for an extremely sharp edge.

One side effect of hardness is brittleness. The soft metal body of the blade absorbs the shock and vibration, protecting the cutting edge. Western chisels are not hardened to Rockwell 64 because their blades would snap on the first use. Japanese chisels overcome this brittleness problem by forge-welding the cutting edge to a much bigger and thicker blade made from softer steel or wrought iron. Sharpening the cutting edge is quick and easy because the hard layer can be kept very thin.

Are you a woodworker with dreams of setting up a fully equipped workshop without breaking the bank? Say goodbye to the frustration of bad tools and costly mistakes with Ralph Chapman’s Ultimate Small Shop Guide. Drawing on over 20 years of woodworking experience, Chapman provides a step-by-step blueprint to help you create a functional workshop for under $1,000. Learn the secrets of tool selection, space optimization, and shop layouts, and discover a hidden source for quality tools at up to 70% off big-box retailer prices. Don’t let common pitfalls derail your woodworking journey—invest in the Ultimate Small Shop Guide and start crafting your projects with confidence today! Advertisement

Are you a woodworker with dreams of setting up a fully equipped workshop without breaking the bank? Say goodbye to the frustration of bad tools and costly mistakes with Ralph Chapman’s Ultimate Small Shop Guide. Drawing on over 20 years of woodworking experience, Chapman provides a step-by-step blueprint to help you create a functional workshop for under $1,000. Learn the secrets of tool selection, space optimization, and shop layouts, and discover a hidden source for quality tools at up to 70% off big-box retailer prices. Don’t let common pitfalls derail your woodworking journey—invest in the Ultimate Small Shop Guide and start crafting your projects with confidence today! AdvertisementThe Back

The entire back of the chisel blade is made from the hard steel. Flattening the back, if necessary, would be quite the ordeal. By design, Japanese wood chisels have one or more hollows on the back of the blade. This greatly reduces the blade’s surface area that would have to be flattened.

This begs the question: What do you do after many sharpenings when the cutting edge has moved into the hollow? No problem. Rework the back until a flat is reestablished near the cutting edge. The hollow extends back and gets deeper at the handle, so you will never run out of the blade.

The Socket-Tang Handle

Japanese chisels have a combination socket and tang arrangement to join the blade to the handle. A cone-shaped ferrule slips over the tang and receives the bottom of the handle while the tang extends into the middle of the handle. The socket prevents the handle from splitting on the lower end, and the tang prevents the handle from loosening. It’s nearly bulletproof in durability.

The Hoop

There is some preparation required with your new Japanese wood chisel. The metal hoop and the wooden mushroom on the handle accept hammer blows without splitting the handle. The hoop is initially set with a small amount of wood sticking out above it. The wood is soaked in water and then hammered down to form a mushroom, locking in the hoop.

You may want to consider getting a Japanese chisel hammer to use with your Japanese chisel. These hammers are lighter, smaller, and easier to control than a large wooden mallet.

Types of Japanese Wood Chisels

The three most common and useful blade profiles of Japanese bench chisels, oire nomi, are the Kinari, Mentori, and Kaku Uchi. Here is a set of the three profiles from KAKURI, made in Japan.

![KAKURI Japanese Wood Chisel Set [Long Handle] 3 Piece for Woodworking, Made in JAPAN](https://wherecanibuythat.us/wp-content/uploads/2023/02/kakuri-chisel-set.png)

The middle chisel, at 15mm (5/8″), is the Mentori. It has a shorter bevel and is a good all-purpose chisel. It has side bevels for paring and heft for chopping.

On the right, the 9mm(3/8″) chisel with its short bevels is called Kaku Uchi. It’s used primarily for chopping mortises and other deep cuts where maximum mass behind the cutting edge is needed.

This particular three-chisel set is used to illustrate the most common blade profiles. It appears to be Kakuri’s consumer offering. We do not recommend it because if you’re going to buy Japanese wood chisels, then get all the manufacturing goodies that make them heirloom quality.

This 12mm (1/2″) Kakuri is hand-forged from white steel for extra sharpness. The handle is white oak.

Some Notes on the Bevel Angle of Japanese Chisels

The bevel angle of Japanese chisels is typically between 30 and 40 degrees. A chisel’s bevel is the blade’s cutting edge, and it’s used to cut materials such as wood, bone, or metal. When sharpening a chisel, the bevel angle should be maintained at a consistent angle. The bevel should be kept at around 30 degrees for the proper use of Japanese chisels.

The bevel angle can be reduced to 28 degrees if sharpening chisels for softwood like pine or spruce. A sharp edge on the chisel makes penetrating the material being cut easier. However, a dull edge may cause the chisel to crack or chip. Regular sharpening and maintenance of the bevel angle are essential for the effective use of your chisels.

Choosing And Mastering The Best Track Saw: 3 Plungers (wherecanibuythat.us)

How to Choose the Right Japanese Chisel for Your Project

There’s much to be said about buying chisels individually and not in sets. If the set contains larger sizes, you will be paying a premium for them and may never need them. Of course, it all depends on what kind of projects you will be working on.

Japanese wood chisels are sized metrically and are slightly narrower than their Western counterparts.

- The smaller widths, 3mm (1/8″) to 12 mm (1/2″), are good for the relatively small dovetails on drawers and for squaring mortises cut by machine.

- The wider chisels are good for larger mortises and dovetails. They all work well for the various paring jobs that always come up when making furniture.

If you inhabit the woodworking forums, you will occasionally see the trope that Japanese chisels are only good on softwoods. That’s nonsense. Tropical rosewood and ebony furniture are common in all of Japan. The most common piece of Japanese furniture, the tansu, a storage cabinet with drawers, is often made with elm, chestnut, mulberry, and other hardwoods.

How Should I Care for My Japanese Wood Chisels?

Caring for and maintaining your Japanese wood chisels is important to ensure that they maintain their sharpness and perform optimally. Here are some tips you should follow:

- Keep the blade sharp by regularly honing the edge with a honing stone or honing oil. This will keep your chisel sharp and ready to use.

- Do not grind to sharpen

- Grinding machines may chip the cutting edge.

- After every use, clean off the chisel with a soft cloth, ensuring no dirt or debris remains on the blade.

- Store your chisel in a dry place, away from moisture, when it’s not being used. This will help prevent rusting and other damage caused by moisture.

- Be careful when handling the chisel; avoid dropping it, as this can cause damage to the blade.

- Do not pry with your Japanese wood chisel. The hard edge is brittle and may chip.

Following these simple steps, you can properly care for and maintain your Japanese wood chisel for years.

Are Japanese Wood Chisels Worth It?

Japanese chisels can be a great investment for your woodworking tool chest. When you want to create art from wood these are your go-to tools. They are well-crafted, durable tools that can provide excellent accuracy and precision when cutting or shaping wood. Japanese wood chisels are typically made from high-quality materials, such as high-carbon steel with hardwood handles, making them more reliable and longer-lasting than other chisels.

Specialty woodworking and hand tool use are part of Japanese culture. You can find Japanese wood chisels in a nearly endless variety of sizes and shapes so that you can find the right tool for any job. Overall, Japanese chisels are worth it if you are looking for a reliable, long-lasting tool to help you complete your woodworking projects accurately and precisely.

People Want To Know

A typical set of oire nomi will range from 3mm to 42mm, a larger set will typically include 1.5mm and 48mm.

Tsuki-nomi are paring chisels, and they come in three basic orientations, which are Tsuki (paring), Usu (thin paring) and Hon-tsuki which are very large timber paring chisels.

As a rule, western chisels are supplied with an angle of 25°, and Japanese chisels with an angle of 30°.

You don’t have to grind the whole bevel; instead, it is enough to grind the first 1 to 2 mm behind the cutting edge.

One should never use dry grinding wheels on fine chisels because they cause the steel to soften, and the cutting edge will last hardly any time.

The Japanese tradition of Sashimono joinery dates back over 1000 years and is now a protected craft.

One of the fundamental elements of Sashimono is reliance on the mechanical strength of the joinery rather than adhesives or fasteners.

Woodworker References

Woodworking with Hand Tools: Tools, Techniques & Projects

The Woodworker’s Bible: A Complete Guide to Woodworking

Japanese Woodworking Tools & Techniques

Choosing And Mastering The Best Track Saw: 3 Plungers (wherecanibuythat.us)

The publisher earns affiliate commissions from Amazon for qualifying purchases. The opinions expressed about the independently selected products mentioned in this content and any instructions or content shared are those of the publisher, not Amazon.

One Comment