Go For A Small Woodwork Shop At Home

Setting up a small woodwork shop in your home requires planning and strategizing beforehand. If you plan to set up a small shop in your home, basement, or car garage, this blog will help you strategize your workshop layout and choose the right tools while keeping safety measures in mind. You can set up a complete, functional shop in 8×8 square feet when done right!

Maximizing Your Woodwork Shop Layout

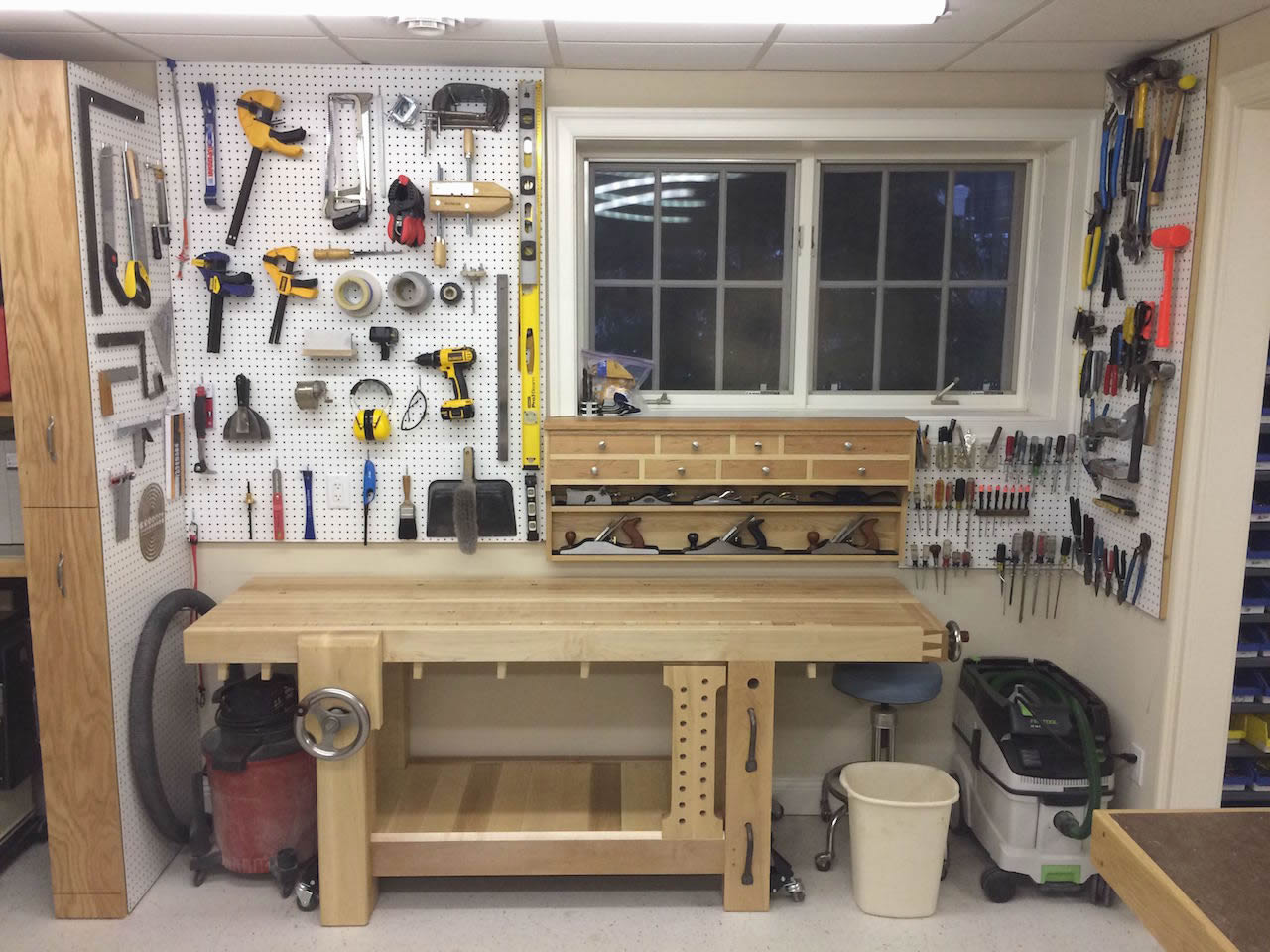

There are several factors to consider. Firstly, you must decide on the size of the shop if that is not already predetermined by what’s available. Second is the layout. This entails measuring the floor space’s size and the height of the walls you have to work with. Third, plan out the workflow. This will help you plan to use every inch of floor and wall space for tool storage, wood storage, work table area, and machinery area.

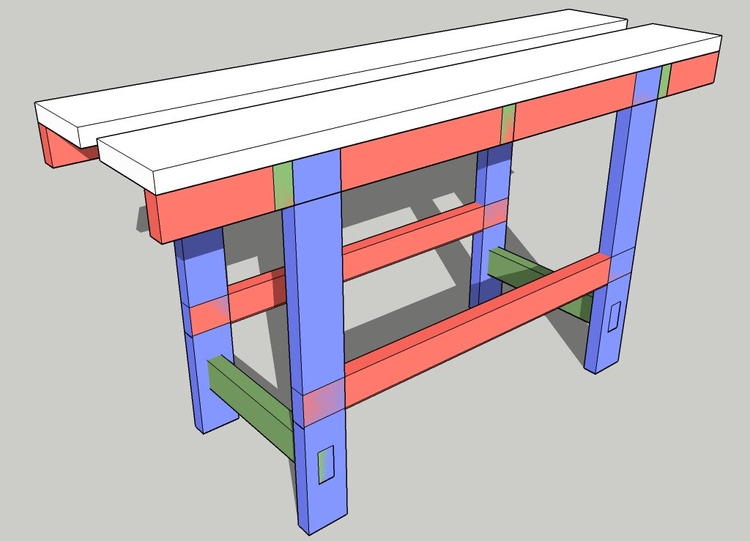

Additionally, having a clear idea of your most likely future woodworking plans and projects is vital. This will help you determine the type of tools and machinery needed and the sizes and shapes that fit into your space. The last but not least point is about setting up the shop efficiently. It’s vital to have a workbench that is adjustable and sturdy. If you can add mobile to that list, you have a winning combination in any size shop.

Are you a woodworker with dreams of setting up a fully equipped workshop without breaking the bank? Say goodbye to the frustration of bad tools and costly mistakes with Ralph Chapman’s Ultimate Small Shop Guide. Drawing on over 20 years of woodworking experience, Chapman provides a step-by-step blueprint to help you create a functional workshop for under $1,000. Learn the secrets of tool selection, space optimization, and shop layouts, and discover a hidden source for quality tools at up to 70% off big-box retailer prices. Don’t let common pitfalls derail your woodworking journey—invest in the Ultimate Small Shop Guide and start crafting your projects with confidence today!

Are you a woodworker with dreams of setting up a fully equipped workshop without breaking the bank? Say goodbye to the frustration of bad tools and costly mistakes with Ralph Chapman’s Ultimate Small Shop Guide. Drawing on over 20 years of woodworking experience, Chapman provides a step-by-step blueprint to help you create a functional workshop for under $1,000. Learn the secrets of tool selection, space optimization, and shop layouts, and discover a hidden source for quality tools at up to 70% off big-box retailer prices. Don’t let common pitfalls derail your woodworking journey—invest in the Ultimate Small Shop Guide and start crafting your projects with confidence today!Advertisement

What do you need to set up a woodwork shop?

In terms of space, a woodshop needs most of its floor area for lumber storage and for the workbench. The walls can be used for tool storage, and with  shelving, lots of other things too. A workshop also needs ample ventilation for safe operation.

shelving, lots of other things too. A workshop also needs ample ventilation for safe operation.

In terms of equipment, it could include power tools such as table saws, routers, and band saws. And it must have portable fire extinguishers and other safety equipment. Finally, it must have a space for drying lumber, too.

If you live in a condo or an apartment or rent external storage, be aware that management may not allow you to use that storage area as your shop, so check before purchasing any items.

Electricity, Lighting and Sound Proofing

Other essentials are:

- reliable power supply – 220v maybe,

- good lighting – bench and area,

- soundproofing to keep the neighbors away.

Lighting is crucial for working in a safe and comfortable environment. Besides, it is also essential for working with power tools. Safety equipment such as goggles and dust masks should be worn while woodworking to minimize the risk of accidents.

Ventilation

Ventilation is essential for a safe and comfortable woodworking shop. To ensure proper ventilation in a small woodworking shop, it is important to consider the size of the shop, the types of tools being used, and any local building codes or regulations that may apply. Some good ventilation methods to use in a small woodworking shop include:

- Installing an exhaust fan can help draw out sawdust and other particulates from the air, ensuring a cleaner and healthier environment.

- Opening windows and doors: If possible, open windows and/or doors to increase airflow and allow fresh air into the space.

- Using an air scrubber: An air scrubber helps to filter out dust particles from the air, making it easier to breathe in the shop.

- Investing in an overhead dust collection system: Installing an overhead dust collection system will help remove sawdust from the workspace, preventing it from becoming airborne and creating unhealthy conditions in the shop.

- Setting up HEPA filters or air purifiers: HEPA filters or air purifiers can be placed throughout the shop to help remove pollutants from the air and make for a cleaner working environment.

Choosing the Right Tools for Your Small Woodwork Shop

When setting up a woodworking shop in your home, it’s essential to consider an organizational plan to keep commonly used items handy and to make work easier. Think in terms of workflow. When you need a clamp, will it be at arm’s length?

Buying the right tools for the job is one of the first steps in planning a woodworking shop. If you are not going strictly with hand tools, then a table saw or a chop saw will likely become the centerpiece of your woodworking shop.

Other hand tools such as measuring tapes, hammers, chisels, hand drills, drill press, miter saws, band saw, screwdrivers, clamps, and wrenches are essential for every woodwork shop. These tools help you perform some tasks more easily and accurately than you can with power tools. Investing in power tools can make work easier and quicker, but to stay within budget you must consider the purpose of each tool and carefully choose only the ones that fit your project plans.

Hand Saws

Hand saws are essential tools for all woodworkers. For example, dovetail saws and carcass saws are necessary for joinery and many other woodworking tasks.

Other common handsaw tasks include cutting boards to length, making rip cuts (lengthwise cuts) or crosscuts (widthwise cuts), making miter cuts (angled cuts), and trimming excess material from project pieces. Hand saws can also be used to create grooves and slots in wood and trim dowels and other small pieces. With a little creativity, you can use hand saws to accomplish almost any task in the woodshop.

Sawhorses

Sawhorses help woodworkers work efficiently and safely by providing a stable work surface for using saws, drills, and other woodworking tools. Sawhorses are made from various materials, from steel to fiberglass or plastic. They can be used in pairs or in larger groups to save space.

Some woodworking shops use knockdown trestle sawhorses, which are easy to build and store away when not in use. These sawhorses consist of a base with two uprights that can be easily knocked down for storage. The uprights can be quickly assembled back into place when needed. This makes them very convenient for working in cramped or limited spaces.

Circular Saw

Circular saws are available as corded and cordless tools, making them ideal for all types of woodworking projects. They are best used for rough carpentry, such as cutting 2x4s or trimming pieces of wood to size. However, circular saws can be used for fine woodworking, as well. The type of blade used will determine the work that can be performed.

Ripping blades are best for removing large pieces of wood with minimal preparation; cross-cut blades are best for cutting through pieces of wood at an angle; and combination blades work best when used in combination with other tools, such as chisels or saws.

Compound miter saws are more accurate at cutting miters, bevels, and compound angles than regular circular saws.

Chisels

Chisels are another must-have tool. They can be used for a variety of tasks, from jointing wood boards to cutting tenon shoulders and defining the edges of dado cuts. Many different types of chisels are available, varying in size and thickness.

Chisels come in various sizes and shapes so that they can be used for a variety of work assignments. They are essential tools for any woodworking shop, so having a good selection on hand is important. Elite woodworkers choose Japanese wood chisels.

Squares

Squares are typically used to align objects or to transfer measurements. They can be made from wood or metal and come in different forms and sizes. They can be used for a variety of tasks, from accurate workpiece alignment and precision measurements to cutting a straight line.

Chances are you will need a small, adjustable square to keep at hand and a large, fixed-size, metal square for the bigger cuts and jobs.

Tape Measures

Tape measures can be used to measure lengths from 30 to 300 feet, and they are always handy to have around your workbench. Steel tape measures come in different lengths, from 12 to 30 feet, while flexible reels can range over 100 feet.

Additionally, woodworkers often use folding rules to ensure accuracy when measuring small pieces of wood. Retractable steel tapes are common measuring tools for woodworkers and come 12 to 30 feet long. They feature a retractable blade that allows them to be easily stored in a toolbox or workbench. You ain’t a woodworker if you don’t have a tape measure hanging from your belt!

Planes

Jack planes remove a lot of material in a single pass. These planes have a long and thin blade, allowing them to cut through wood at a very shallow angle. This makes it easy to work with precision and achieve smooth results.

Other types of planes that woodworkers can consider include jointers, blocks, and spokeshaves, designed for different purposes and working with various types of wood. Router planes are another descendant of the hand-powered tool, and they are useful for a variety of tasks. These planes have specialized heads that allow them to perform specific functions such as routing or finishing work. They are often used in woodworking shops for quick precision work around the shop.

Different types of planes have different blade sizes and depths that affect how much material can be removed at once. Keep in mind that planes are cutting tools, not abrasive sanding devices. They should only be used on workpieces that can take abuse without being damaged or distorted.

Hand Files

Hand files are also essential tools for woodworking. They are available in a variety of shapes and sizes to suit different types of woodworking, from smooth surfaces like table tops and cabinets to more detailed work like furniture making or siding.

Common hand files range from coarse to fine, creating various levels of precision and finish. These files are used to smooth rough edges and create curved shapes in wood, such as when creating detailed work like carvings or decorative patterns.

Hand files are relatively inexpensive so they can be found at most hardware stores. Hand files must be stored safely when not in use to ensure safety and prevent accidental damage. They should always be handled with care and precision to avoid accidents or harm to the surrounding area.

Storage Solutions for Your Shop

Analyze your shop’s floor plan and determine the best woodworking equipment and storage locations.

- Maximize the floor space by storing wood pieces or sheet goods near the front of the shop or workbench.

- Utilize the air space overhead by creating a set of inexpensive metal shelves.

- Dedicate a cabinet for raw pieces of wood and another for unfinished workpieces.

- Consider plywood boards and other sheet goods in planning your floor plan.

- Make use of small parts by constructing a rotating bolt cabinet.

With these simple suggestions, you can create a space-efficient shop with ample storage options.

Planning Ahead for Future Projects

Start planning for woodworking projects in your home by taking the time to consider the size and scope of your projects. This will help you identify the necessary tools and supplies to complete the work. If there’s a thickness planer, a lathe, or a router table in your future, you almost have to start planning it for now.

6 Tips for Optimizing Your Small Woodworking Shop (wherecanibuythat.us)

Make sure you have adequate ventilation and dust collection systems. This will help ensure your workspace is free of harmful fumes and particulates. Plus, these systems can help you track your work and make it easier to find items when needed.

Also, invest in a good workbench suited to the type of work you will be doing. A workbench should be sturdy and able to support your tools and materials without tipping or slipping. A workbench should also be easy to clean and provide a comfortable seat while working.

Finally, setting up a small woodworking shop means having a plan for organizing and storing tools, materials, and supplies. This will help keep your workspace clutter-free and make it easier to access items when needed.

Designing a Safe and Efficient Small Work Area

Start with a clean space. A work area should be well-ventilated and clutter-free. Choose tools and equipment that help you work efficiently and efficiently plan your work for the day. A shop vacuum should be at the top of the list.

Start with the items you need to complete the project. Keep your workspace organized by using organizers, drawers, and racks.

To start on a project, prepare yourself and your environment. Keep your hands clean and dry, wear protective gloves and goggles, and use mops or brushes to remove debris from the workspace.

Using clamps or other safety devices to avoid splinters or saw injuries when working with wood.

Also, invest in the right tools, such as saws, power tools, hand saws, hammers, drills, sanders, saw blades, miter saws, and workbench accessories to help you work efficiently.

What safety measures should you take while setting up a woodwork shop?

Before starting a woodworking project, you must be aware of safety measures. If your workshop is clean and organized, it will help you minimize the risks of woodworking. Besides, investing in a cyclone dust collection system will keep your workspace clean and hygienic.

When working with tools, it is important to have a tool chest that ensures the safe storage of your tools. Finally, it is vital to keep your workspace well-lit to view workpieces clearly. You must wear protective clothing and safety gear while working to ensure complete safety during woodworking projects.

Conclusion

A small woodwork shop of your own will give you the freedom to work on projects whenever you want and create whatever designs come to mind. You can also exercise your creativity while working on wood projects, which can be a fulfilling experience. If you don’t have space for an entire woodwork shop, you can start small by setting up an area in your home for woodworking and creating tools for specific projects. This way, you’ll still be able to work on wood projects and enjoy the benefits of woodworking. Popular Woodworking always has some good ideas.